| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : Sheng Rui

Model Number : SR-MI11

Certification : ISO9001: 2015

Place of Origin : Dongguan, China

MOQ : 1 PCS

Price : Negotiable

Payment Terms : T/T 30% as deposit

Supply Ability : 1200-1400 units per month

Delivery Time : Normally, simple parts, 7-15 days, complicated parts 15-20 workdays, according quantity and the complexity of drawing.

Packaging Details : Anti-Rust Oil, PE film covered first, Foam box, then carton

Shaping mode : Plastic Injection Mould

Product : Household Appliance,Vehicle Mould

Mould life : 250000-300000shots

Surface treatment : Texturing or Polishing and so on

Mould base : LKM or HASCO and so on

Keyword : plastic injection syringe mold

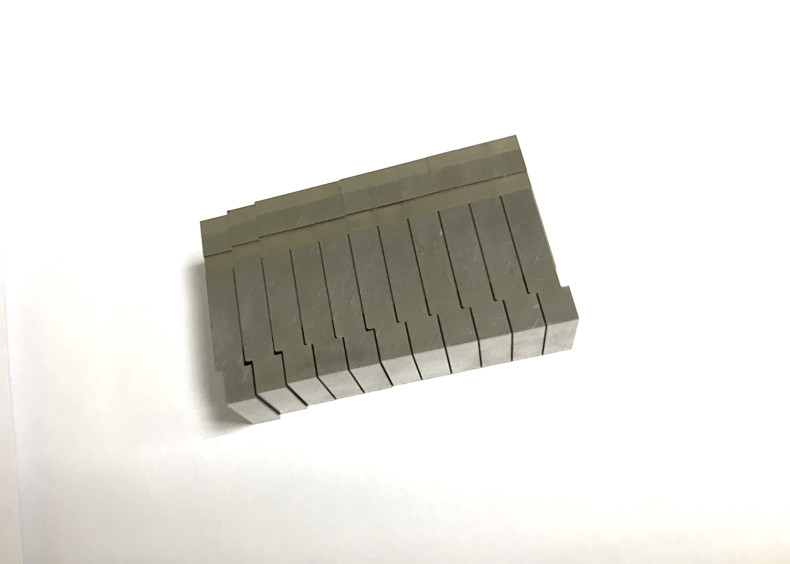

Customized Medical Injection Molding Parts Plastic Injection Molded Components

Product Information:

| Product Type | Custom Plastic For Injection Moulding,Plastic Injection |

| Our Services | CNC Machining,Plastic Injection,Stamping,Die Casting,Silicone And Rubber,Aluminum Extrusion,Mould Making,etc |

| Material | Aluminum,Brass,Stainless Steel,Copper,Plastic,Wood,Silicone,Rubber,,Or as per the customers’ requirements |

| Surface Treatment | Anodizing,Sandblasting,Painting,Powder coating,Plating,Silk Printing,Brushing,Polishing,Laser Engraving |

| Drawing Format | .jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Packing | Foam, Carton, Wooden boxes, or as per the customer’s requirements |

| Near Port | Shenzhen |

Application:

Automotive Connector Mold

Precision Connector Mold

Injection Products

Precision Powder Metallurgy Mold

Powder Injection

Die-Casting Mold

Vehicle Mould, etc

Our Spirit:

From hardware mould, plastic mould to precise parts processing,

We continuously introduce high-precision mould processing equipment and perfect the operation system.

Meet the personalized demands of customers,

Make the mould manufacture with higher quality and efficiency.

Why Choose Us?

1.Competitive price and good quality product.

2. Perfect quality control during the whole process

2. Experienced engineers and Precision machine.

3. Tight tolerances for precise parts;

4. Successful cases with clients and High praise rate.

Good Service:

1 . Flexible lead time;

2. weekly report of the product manufacture.

3.full follow-up system to fullfill your projects;

4. Timely reply. (at work time will repond in two hours, after work time will reply as soon as possible).

Material hardness comparison:

| 8407 | HRC52-54 |

| HPM31 | HRC56-58 |

| PD613 | HRC56-58 |

| S-7 | HRC54-56 |

| M390 | HRC58 |

| SKD61 | HRC52-54 |

| 1.2344 | HRC 52-54 |

| DC53 | HRC56-58 |

| ASSAB88 | HRC58-60 |

| A2 | HRC56-58 |

| 1.2767 | HRC52-54 |

FAQ

Q: Are u a Manufacturer or a Trading company ?

A: We are manufacturer in guangding China.and have foreign trading experience two years.

Q: Do u support ODM/OEM OR customize?

A: Yes,ODM/OEM or customization are available.

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or sample of your product. Details below should be included:

1.Materials 2. Surface Finish 3. Tolerance 4. Quantity 5.other special requirements

|

|

Medical Sleeve Ejector Injection Moulding CNC Machining With Painting Images |